RTO insulation design guidance

RTO / RCO insulation design guidance

1.Overview

RTO is an important device in the process of volatile organic compounds (VOCs) pollution prevention and control. It is mainly composed of combustion chamber, regenerator, collection chamber, high-temperature air duct, chimney and control system, and some also include mixing chamber. According to the shape, it is also divided into box type or rotary type. The box type has two rooms (or box), three rooms, five rooms and seven rooms, and the rotary type also has round and square according to the shape.

Since RTO burns organic waste gas, it needs fire-resistant and thermal insulation treatment. The selected fire-resistant and thermal insulation materials are mainly aluminum silicate fiber products (also known as ceramic fiber products or fire-resistant ceramic fiber products), and the assembly room is mainly refractory castable.

2.RTO mainly uses refractory insulation materials

(1) Refractory ceramic fiber products

It is also called aluminum silicate fiber products. According to the classification temperature, it mainly includes 1260 type and 1430 type. The actual use temperature is 1000 ℃ and 1200 ℃ respectively. The commonly used 1260 type. At present, the 1260 type products used in RTO in China are also divided into ordinary type, standard type and high-purity type according to different raw materials. 1430 type products are divided into high aluminum type and zirconium type.

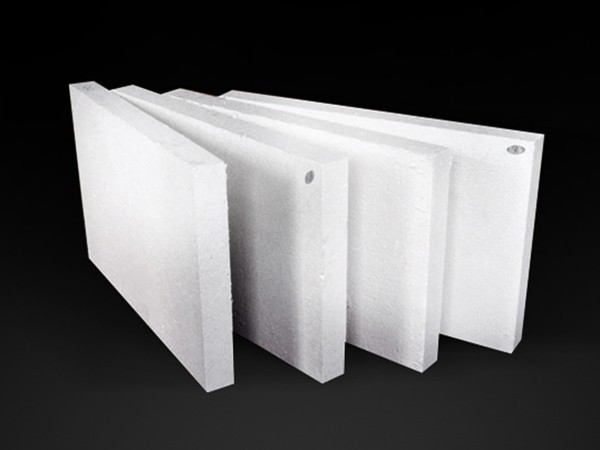

According to the use situation, the refractory ceramic fiber can be processed into modules, blankets, plates, cotton, special-shaped parts and other forms for use in different environmental occasions. Refractory ceramic fiber module is used in combustion chamber, regenerator, high temperature air duct and other parts because of its resistance to air flow erosion and easy installation. Refractory ceramic fiber blanket is mainly used for the backing layer of ceramic fiber module, compensation blanket and external insulation of pipeline. Refractory ceramic fiber board is mainly used for regenerator partition wall. Refractory ceramic fiber cotton is mainly used to fill the gap between partition wall and heat storage body. Refractory ceramic fiber shaped parts are mainly used for heat insulation of high temperature valves.

In terms of service temperature, raw material quality and product price, from low to high, it is ordinary type - standard type - high purity type - high aluminum type - zirconium containing type. Some refractory ceramic fiber enterprises also have a product between ordinary type and standard type called semi standard or 1140 type. At present, the standard type is mainly used in some small RTOS. From the perspective of use safety, service life and economy, standard refractory ceramic fiber products can be selected for RTOS with service temperature below 900 ℃, high-purity refractory ceramic fiber products can be selected for RTOS with service temperature below 900 ℃ - 1000 ℃, and high aluminum or zirconium containing products should be selected for RTOS greater than 1000 ℃.

Because most users do not know about refractory ceramic fiber products, they do not know how to distinguish them when selecting them, which requires professional personnel or enterprises with good reputation to help them select or identify, and confirm qualified suppliers through comparison and introduction of multiple enterprises, so as to avoid being shoddy and replacing high with low. Although there is no problem in the short term, once it is used for a long time, its danger will exist. In particular, some large chemical enterprises mainly carefully consider the safety factors in the selection of refractory ceramic fiber products, not just the price, which will bring potential safety hazards to the later stage.

At present, refractory ceramic fiber manufacturers rarely mark the chemical composition on the product manual, because the chemical composition is also one of the means of product quality identification. At the same time, as a customer, if sampling is sent to the national testing agency for testing, it will not only be too late, but also expensive testing costs. Therefore, it is a good way to choose a reputable cooperative supplier or a professional and technical personnel of refractory fiber with many years of experience.

(2) Heat resistant steel anchor

Heat resistant steel anchors are mainly used to fix refractory ceramic fiber products or refractory castables. According to the service temperature, the materials of heat-resistant steel anchors include SUS201 \ sus303 \ SUS310, etc. According to different installation methods, the refractory ceramic fiber module can choose different anchor structures, including angle iron, butterfly, A-frame, slide, diamond and other forms. At the same time, quick cards, staples, etc. are also used as supporting facilities for construction.

Due to different service temperatures, anchors of different materials need to be selected, which is also one of the materials that make it difficult for users to control the quality of anchor nails. In many cases, there is a situation of replacing high with low, which is the same problem as the selection of refractory ceramic fiber products.

The price of anchors with different materials and structures also varies. How to select and hold them according to the RTO installation can not only ensure the safe operation of RTO, but also take into account the comprehensive cost.

(3) Surface curing agent

The main component of the surface curing agent is silica. The specification can be selected from 10% to 40%, and the common concentration is 30%. At the same time, it can also be divided into alkali type, acid type, amine type, etc. according to the use environment. Because of its different particle size and concentration, the price difference is also large. At present, the surface curing agent with alkaline concentration of about 30% and particle size of 30um is mainly used in RTO.

The main function of surface curing agent is to form a layer of hard shell on the surface of refractory ceramic fiber products to improve the anti air scour ability of refractory ceramic fiber products. Since the selection of refractory ceramic fiber module has the ability to resist air scour in RTO, there are two situations in the selection of surface curing agent: use and non use. If the selected surface curing agent is appropriate, It can be selected. If it is not selected properly, it makes no difference whether it is used or not.

When using the surface curing agent, pay attention to the occurrence of surface migration. It is best to dry it at 60 ℃ - 80 ℃, otherwise it is easy to peel and fall off.

(3) Other materials

RTO also uses some refractory castables, rock wool, stainless steel foil, aluminum foil or anti dew point coating, but the amount is small, so it will not be introduced separately here.

3.Installation

The installation of refractory ceramic fiber products is an important control part of the whole RTO lining. Due to the uneven quality of installation personnel at present, there is a phenomenon of cutting corners in the installation of ceramic fiber products, mainly as follows: 1. The spacing of anchor nails is larger than the size of the drawing to facilitate installation; 2. The welding quality of anchor nail does not meet the requirements and is easy to fall; 3. Reduce material consumption; 4. Whether the curing agent is sprayed and its uniformity cannot be verified; 5. Whether the material selection of welding rod is consistent with that of anchor; 6. Whether the module is filled after pulling out the plastic pipe; 7. Whether the tile blanket is staggered; 8. Whether the joint of compensation blanket is staggered, etc.

See ceramic fiber installation manual for specific installation methods.

- Last:Nothing

- Next:RTO outer wall temperature and thickness table